Frequently Asked Questions

NOTE

The content on this page is compiled from group chat discussions and personal experiences, and may not be 100% accurate.

Most issues are caused by poor soldering techniques - please check your PCB soldering first!!!

Firmware Related

Unable to remove write protection/firmware flashing issues

Check the following:

Have you installed the USB-to-TTL (serial) module driver? Typically the CH340 universal serial driver.

Have you selected the correct processor model 'CH32V203' and download method 'Serial'?

Is the correct COM port selected? (Check under Device Manager > Ports (COM & LPT) for the port number matching your module's chip, then verify in flashing software)

If the port appears in Device Manager but not in flashing software, click 'Search' then expand the dropdown to select

Correct wiring connections:

Board Module V+ 3.3v GND GND TX RX RX TX A very few modules require TX-TX/RX-RX connections (e.g. ESP01S dedicated modules) - refer to product documentation

Correct button sequence:

- Connect DuPont wires and plug serial module into computer

- Hold 'B' button, briefly press 'R' button

- Remove protection and flash firmware on computer

Recommended to hold B button throughout the entire process

Check PCB soldering for cold joints, missed connections, or solder bridges

For CH340/CP2102 modules: Try clicking Download > Enable Auto Download > Confirm > Download again > "Write Protection Enabled" prompt appears. This usually occurs when the chip already has firmware.

For other modules: Consider purchasing CH340/CP2102 modules like this one

(370 version) Motor rotates in wrong direction

Usually caused by firmware auto-direction detection failure. Solutions:

- Reflash firmware

- Disconnect problematic channel > Restart BMCU (press R) > Reconnect channel > Restart BMCU

- Alternatively, simply swap the motor's positive/negative wires

Filament Loading/Unloading

Filament position detection failure/abnormal movement

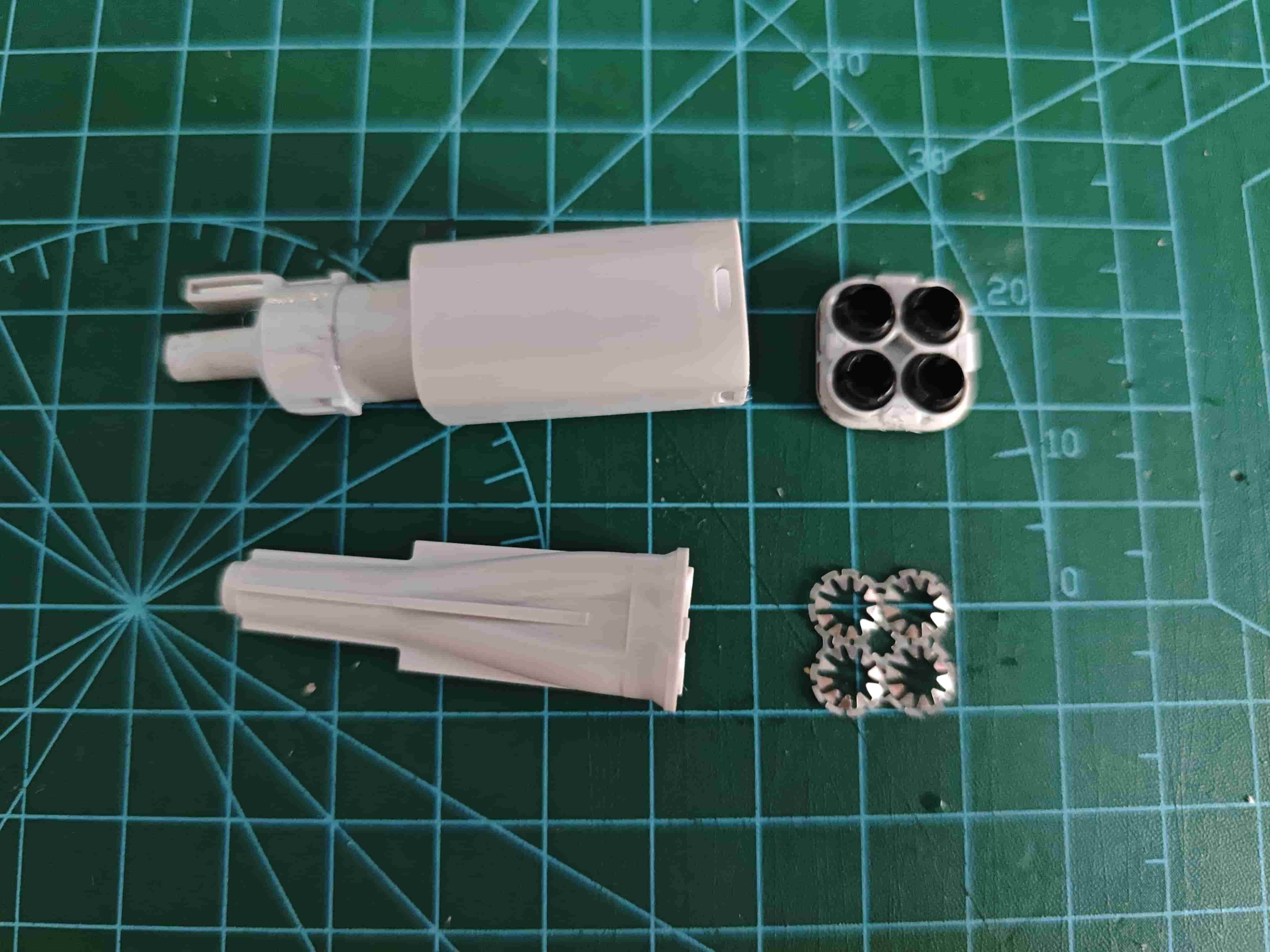

Usually caused by magnet or magnetic encoder (5600 chip) issues. Verify:

- Using radial magnets

- Extruder gear with set screw is not on the wrench

- Set screw is tight

- PCB soldering is correct

(130 version) Triangle plate spins freely with motor - only loads/unloads

Caused by insufficient triangle plate resistance. Solutions:

- Apply damping grease to triangle plate gear

- Apply small drop of 502 glue to gear shaft (face downward to prevent runoff), rotate gear before fully dry

- Redesign/print triangle plate using models like

@xiaoxinleziren's design or spring-loaded versions - Some users mount BMCU sideways to eliminate gravity effects

(130 version) Gear clicking noise during motor rotation

Worm gear not inserted deeply enough. For original 'Mabuchi FF130-SH' motors, insert worm gear flush with motor shaft. For other motors, experiment with depth.

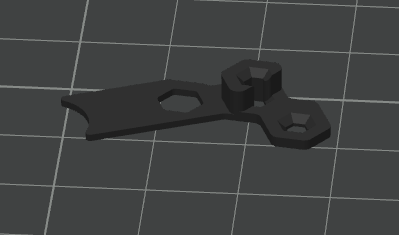

For original-style housings, check if gear bracket is installed:

Also ensure proper gear lubrication to prevent future issues

PTFE tube won't stay in five-way connector

Solution: Disassemble five-way connector, flatten metal clip slightly, and ensure PTFE tube near extruder is vertical

(370 version) Five-way connector failure

- Confirm firmware version - versions before 3-14 are more prone to failure

- Use extended buffer modification or external buffer (recommended)

- Use five-way reinforcement (temporary fix, best combined with above)

- Switch to BMCU-C Hall effect version (permanent solution)

Find related models on Makerworld

During Printing

Frequent filament purging during prints

Likely caused by filament length detection issues. Possible causes:

- Radial magnet not rotating with BMG gear

- Using 3mm ID PTFE tube between BMCU and printer reduces buffering

- Excessively long PTFE tube sections

- Non-standard filament diameter (unconfirmed theory)

More Issues

Visit the FAQ section of the 130 installation guide for additional troubleshooting.